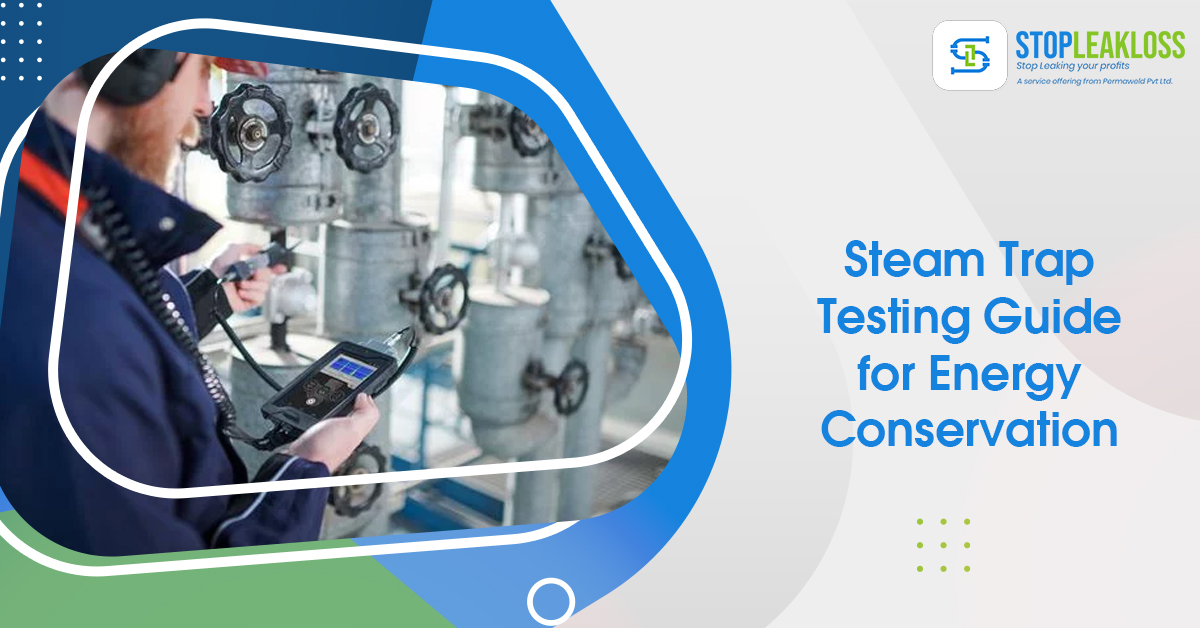

Steam Trap Testing Guide for Energy Conservation

Steam trap testing- This blog will explain the energy savings potential of steam traps and the energy, economic, and environmental reasons why an active steam trap maintenance programme is beneficial to the organisation’s bottom line. Each area will be discussed in detail, and some new services, products, techniques, and technology that may assist maintain or